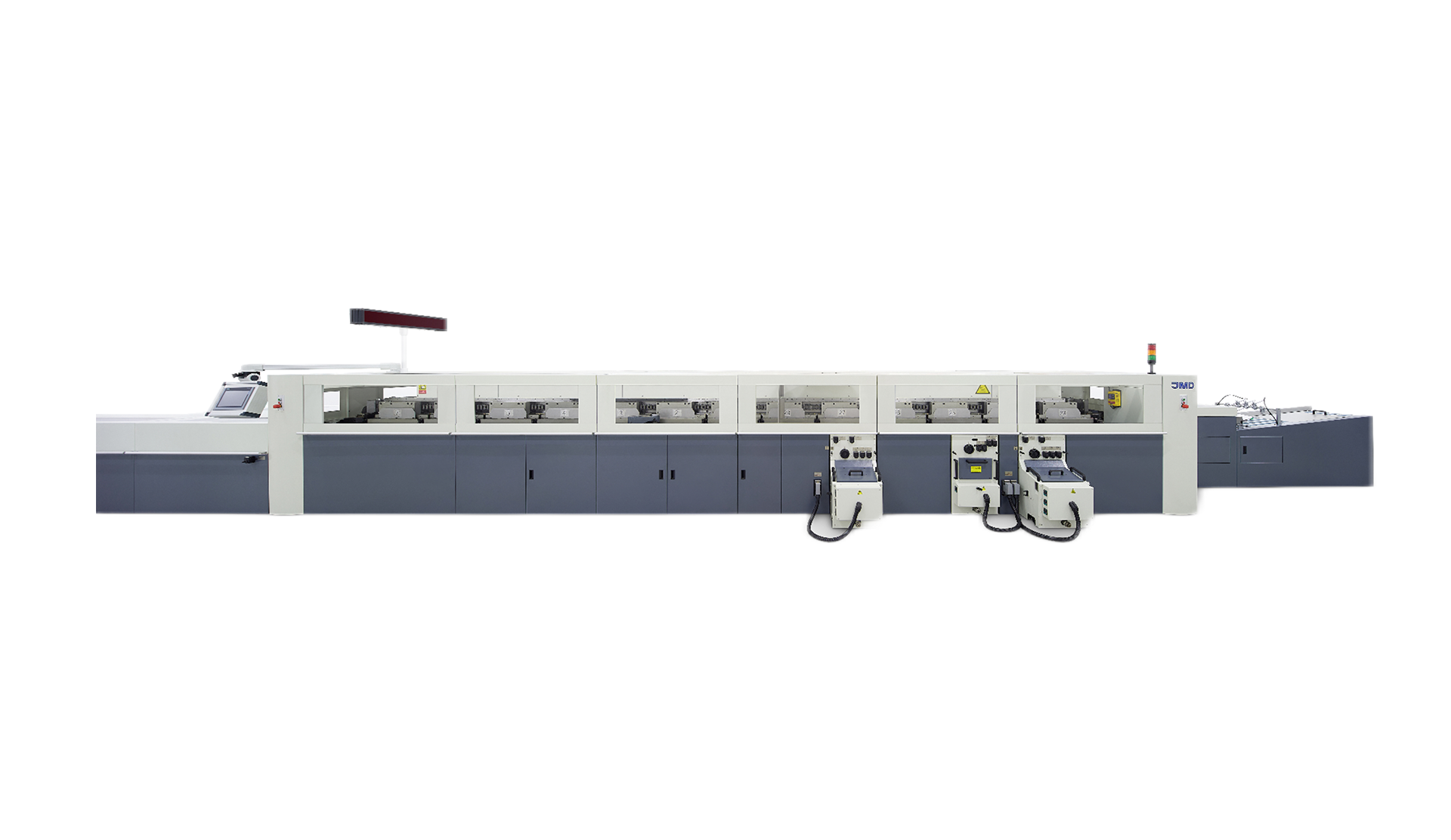

Cambridge-12000 Perfect Binder

The Cambridge-12000 Binding System is the most efficient and the most impressive high performance perfect binding line from JMD. It features high production speed, short make-ready time and outstanding binding quality. Cambridge-12000 Binding System is an ideal choice for large printing houses to improve production efficiency and save labor cost.

Outstanding Features:

♦ High production speed up to 10,000 books/hour can be achieved, which increases greatly the net output and cost-effectiveness.

♦ The whole system is designed with European top quality standards, which ensures a strong stability even at very fast running speed.

♦ Two spine glue tanks and two nipping stations ensure a strong and accurate outstanding binding effect with perfectly-shaped book spines.

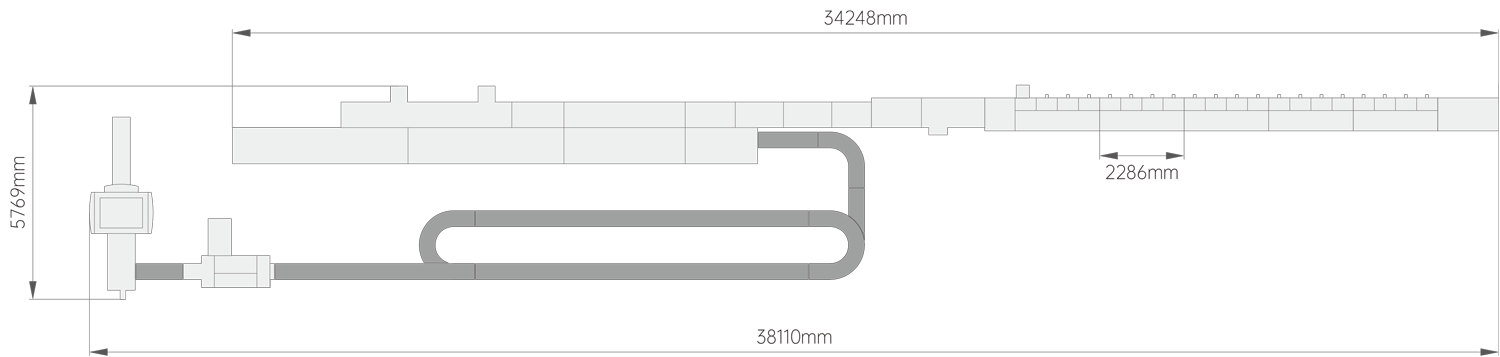

Machine Layout:

|

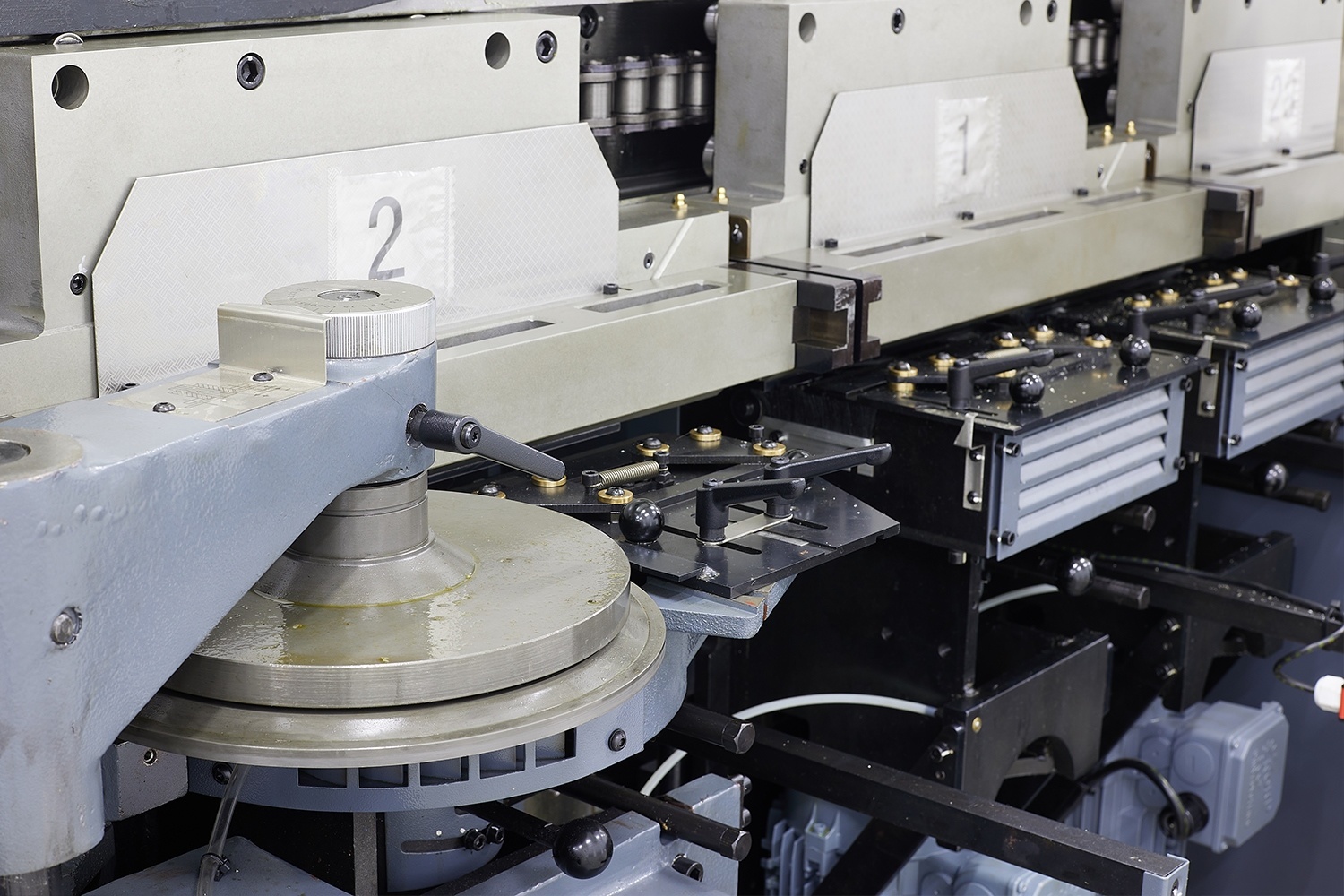

Servo Motor Controlled Book Clamps

All book clamps provides stable clamping force to ensure high accuracy of each production step. Controlled by servo motor, the opening width of book clamps is fully automated adjusted. |

|

Spine Preparation Stations

Three separate spine preparation stations provide for spine roughening, milling, notching and brushing. The height of roughening, milling and notching stations are auto controlled by servo motors, with milling accuracy down to 0.1 mm. |

|

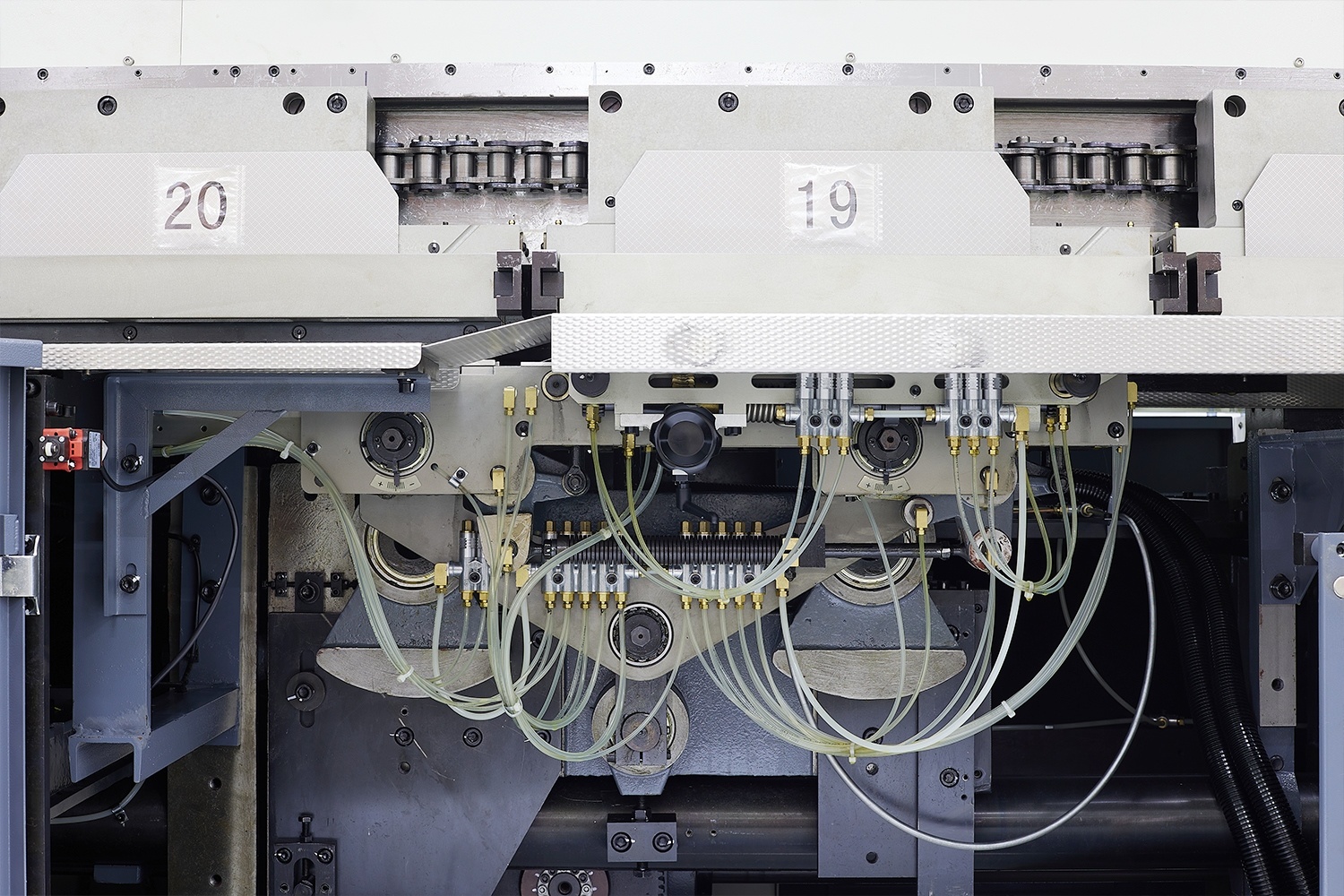

Gluing Application System

Double spine gluing stations with one side gluing station guarantee optimal gluing effect. |

|

Two Nipping Stations

Two superior nipping stations exert powerful nipping pressure to create strong and durable binds with perfectly-shaped book spines. |

|

Machine Model |

Cambridge-12000 |

|

No. of Clamps |

28 |

|

Max. Mechanical Speed |

10000 c/h |

|

Book Block Length (a) |

140-510mm |

|

Book Block Width (b) |

120-305mm |

|

Book Block Thickness (c) |

3-60mm |

|

Cover Length (d) |

140-510mm |

|

Cover Width (e) |

250-642mm |