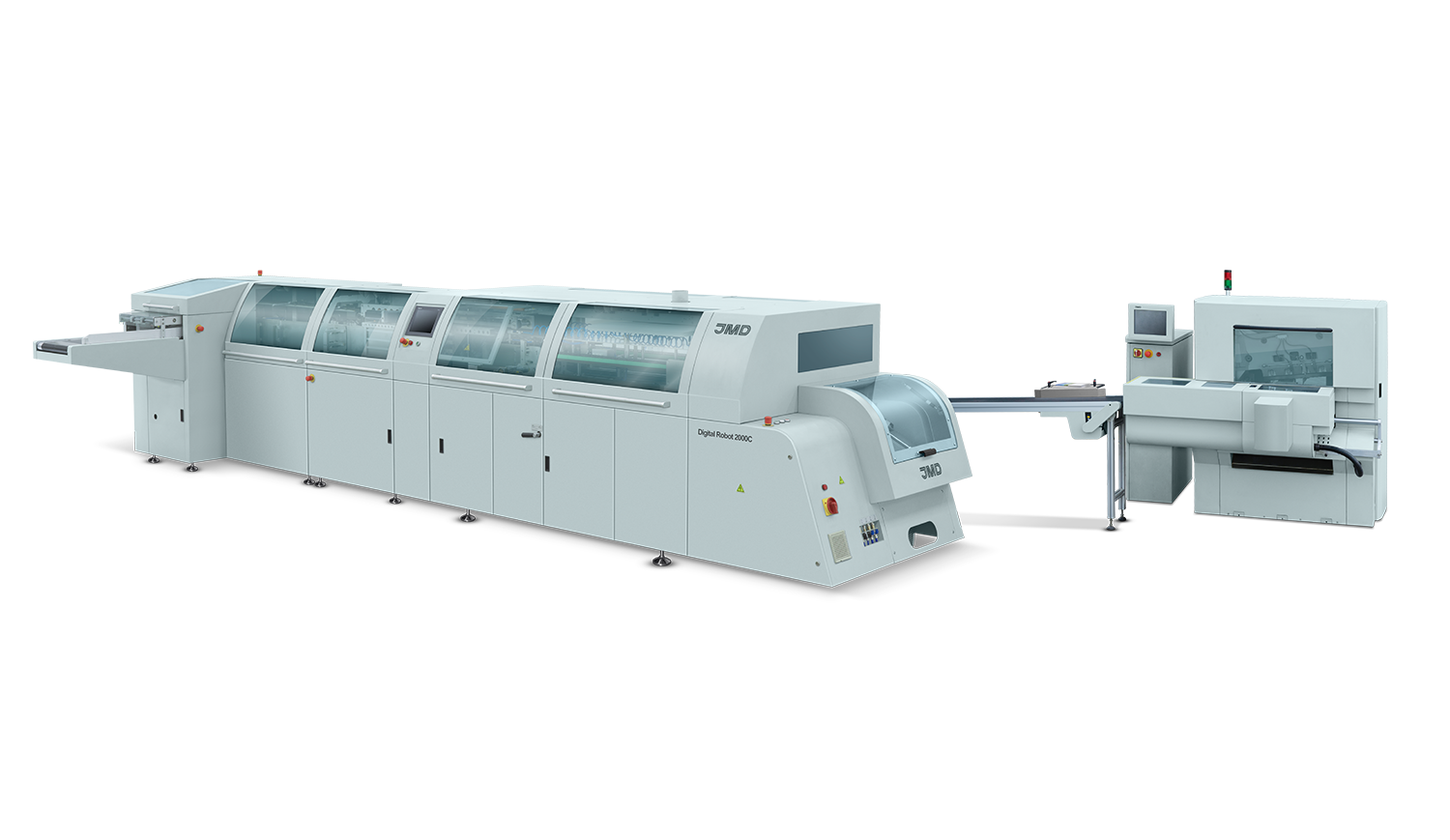

Digtal Robot 2000C

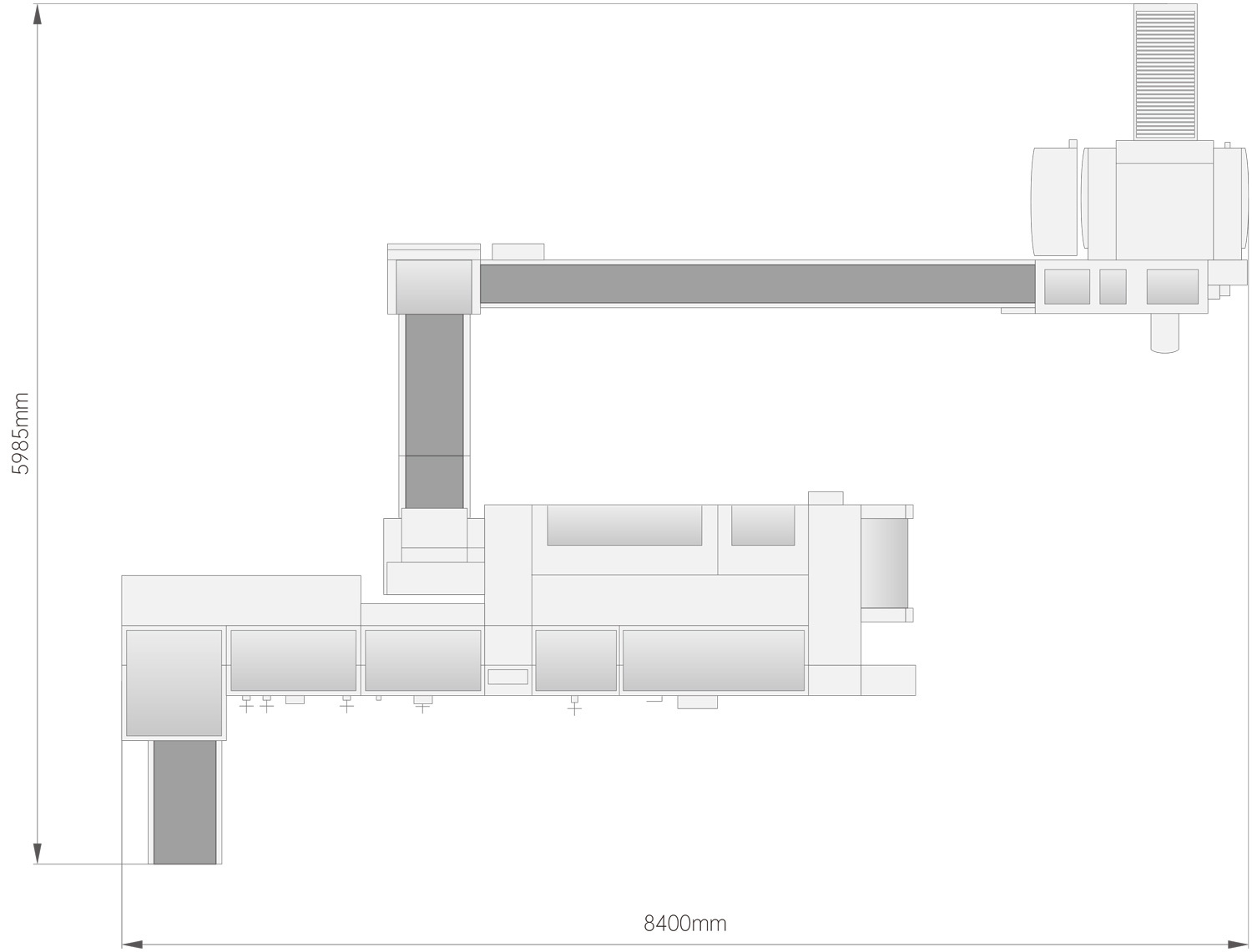

Machine Layout:

Machine Details:

|

|

|

Robot Arm

Smart robot arm controlled by servo motor can automatically and precisely feed the book blocks. |

|

Central Control System

Icon-based touch screen serves as a central control and monitor system of all modules. 99 jobs can be stored and accessed again for for repeat jobs. |

|

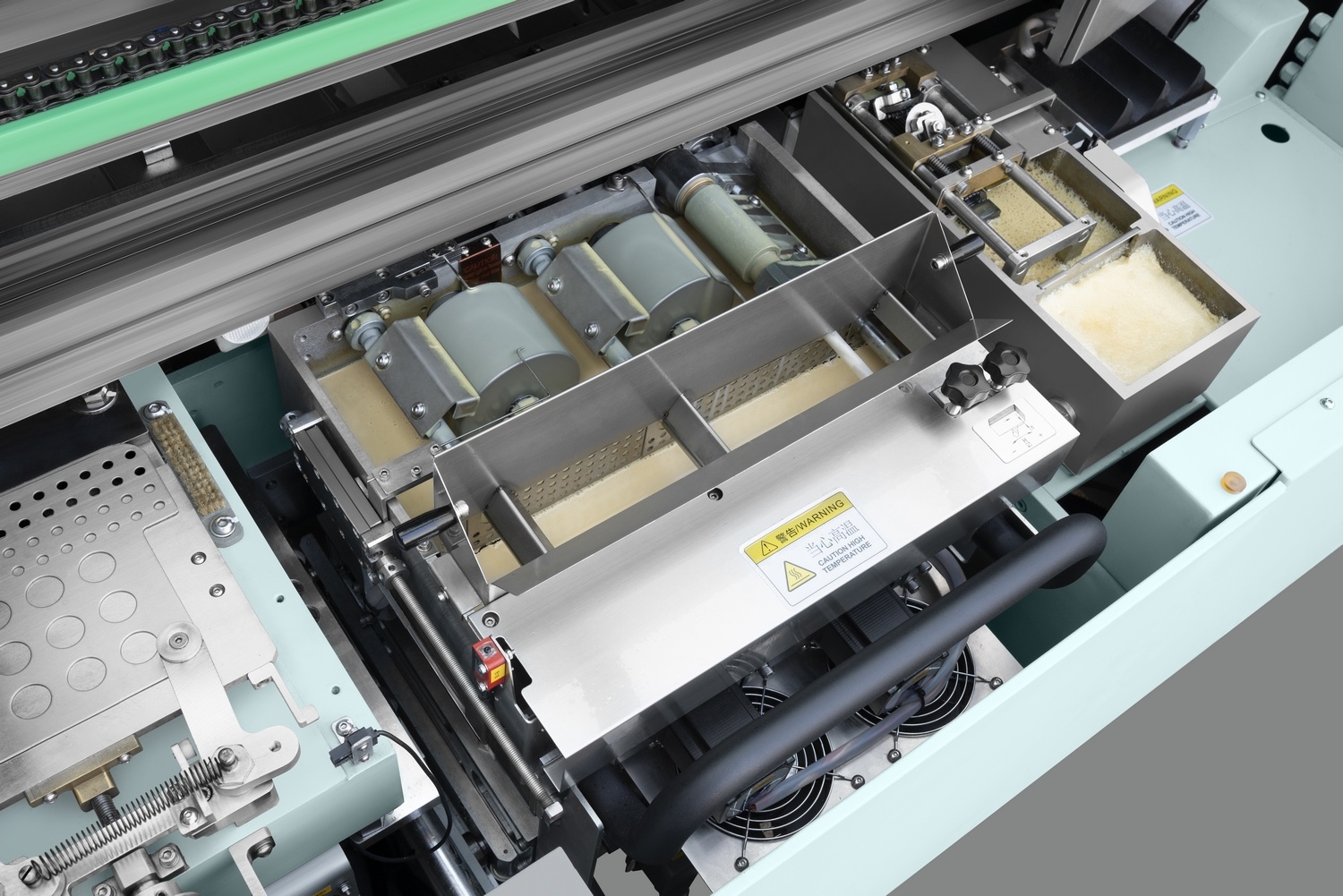

Spine Gluing Station

Side Gluing Station

|

|

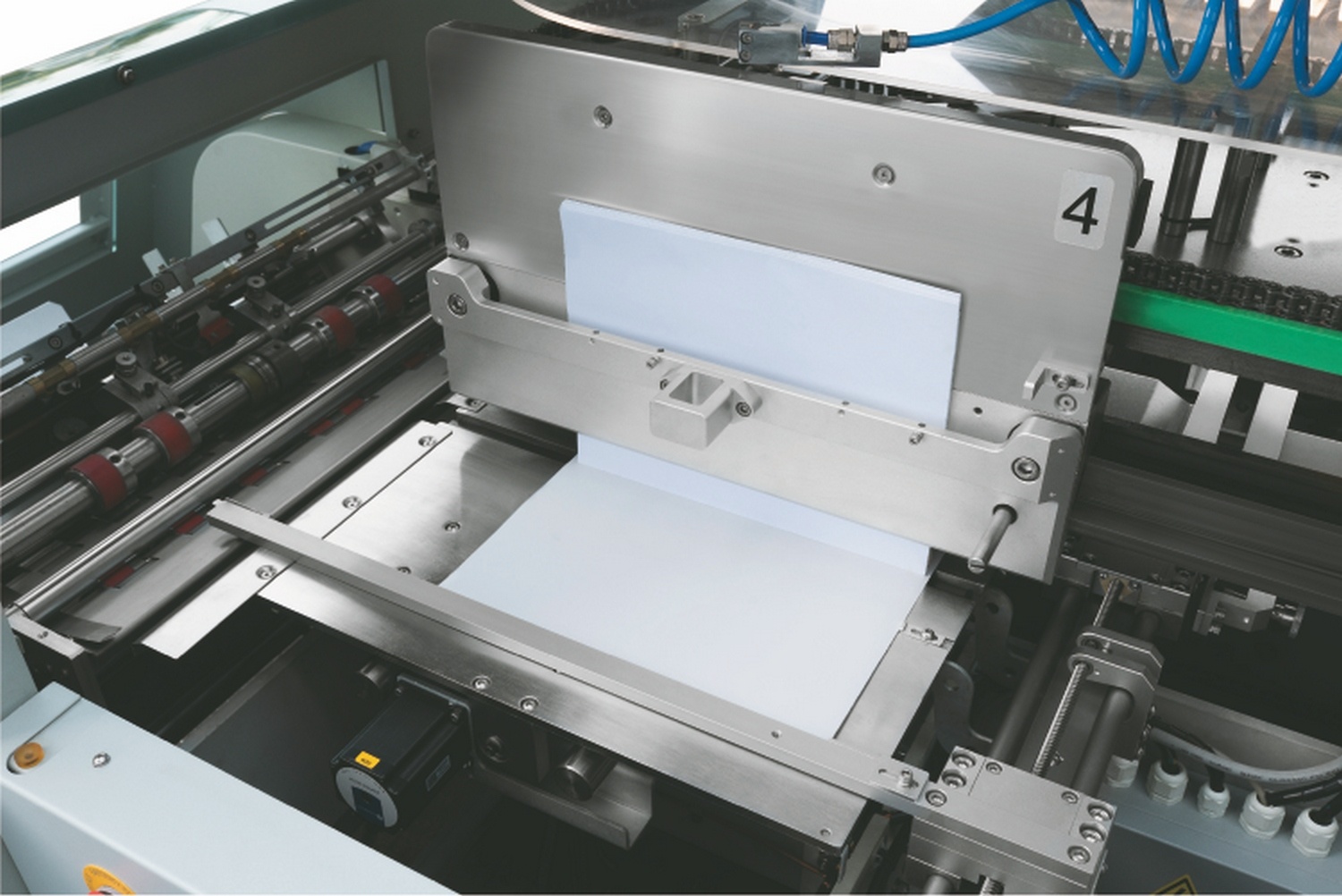

Cover Feeding Station

The special bottom in-feed design allows cover sheets to be added on the fly without interrupting production. The side gauges of the cover feeding station and the position of the cover scoring wheels are automatically adjusted based on the input data. |

|

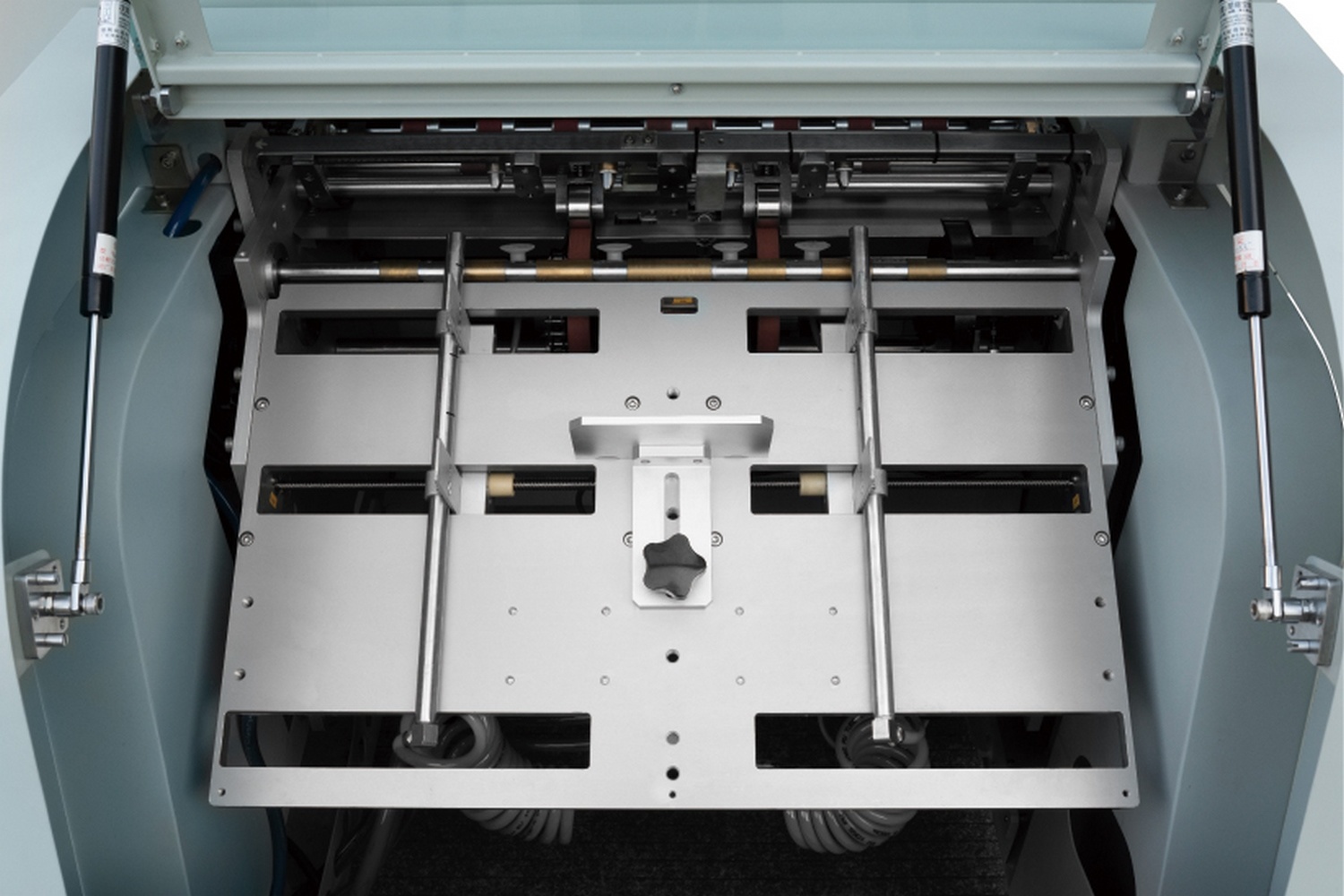

Nipping Station

Thanks to the strong and rigid nipping mechanism, covers can be precisely and firmly nipped with the book blocks to obtain perfectly-shaped book spines. The opening width of nipping plates and side gauges are automatically adjusted. |

Machine Technic Data:

|

Machine Model |

Digital Robot 2000C |

|

No. of Clamps |

4 |

|

Max. Mechanical Speed |

1600 c/h |

|

Book Block Length (a) |

140-320mm |

|

Book Block Width (b) |

120-270mm |

|

Book Block Thickness (c) |

3-50mm |

|

Cover Length (d) |

140-450mm |

|

Cover Width (e) |

250-590mm |