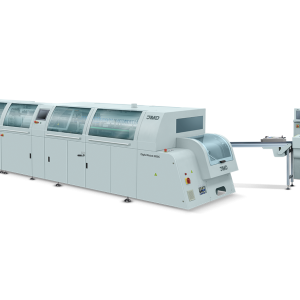

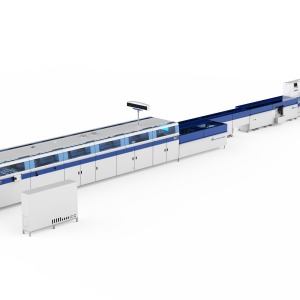

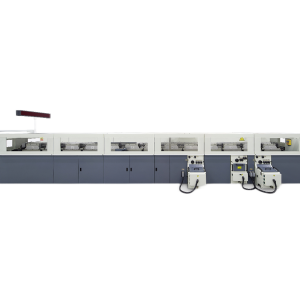

Superbinder-200E Perfect Binder

Superbinder-200E is an excellent four-clamp perfect binder with max. mechanical speed up to 2,000 cycles per hour. It employs the modern industrial design, and new upgrades on the critical stations for quick changeover and superior binding quality. Superbinder-200E is an ideal solution to fulfill your every demand for both digital and offset production with maximum flexibility.

Outstanding Features:

- Quick Setup & Precise Adjustment: The touch screen control system and position indicators facilitate easy setup and precise adjustments.

- High Production Efficiency: Achieve binding speeds of up to 2,000 cycles per hour, delivering exceptional binding quality for both digital and offset production.

- Quality Assurance: Reliability and performance are guaranteed through the use of world-class brand components.

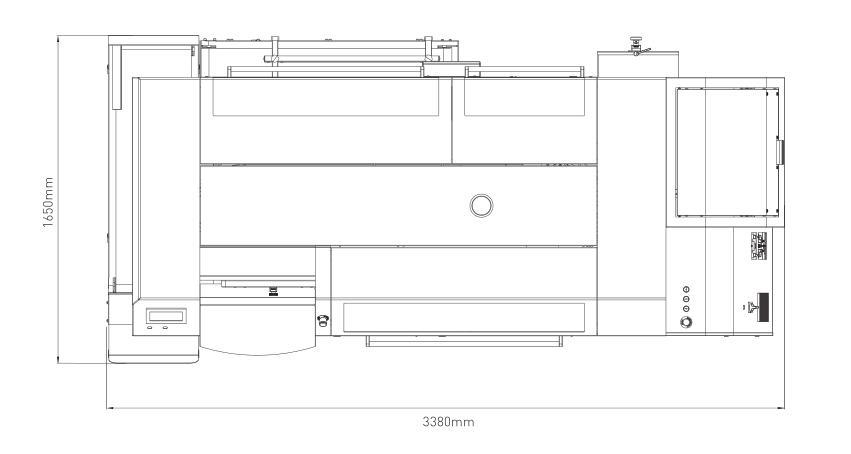

Machine layout:

|

Touch Screen Control System

The icon-based 10-inch Schneider touch screen provides easy set up and convenient operation, which also serves as the fault monitor. |

|

Book Block Feeding Station

Upgraded four cast-made book clamps with double screw rod design and position indicator, allowing easy adjustment. Book in-feed station height is adjustable, integrated with auto aligning device for book blocks. |

|

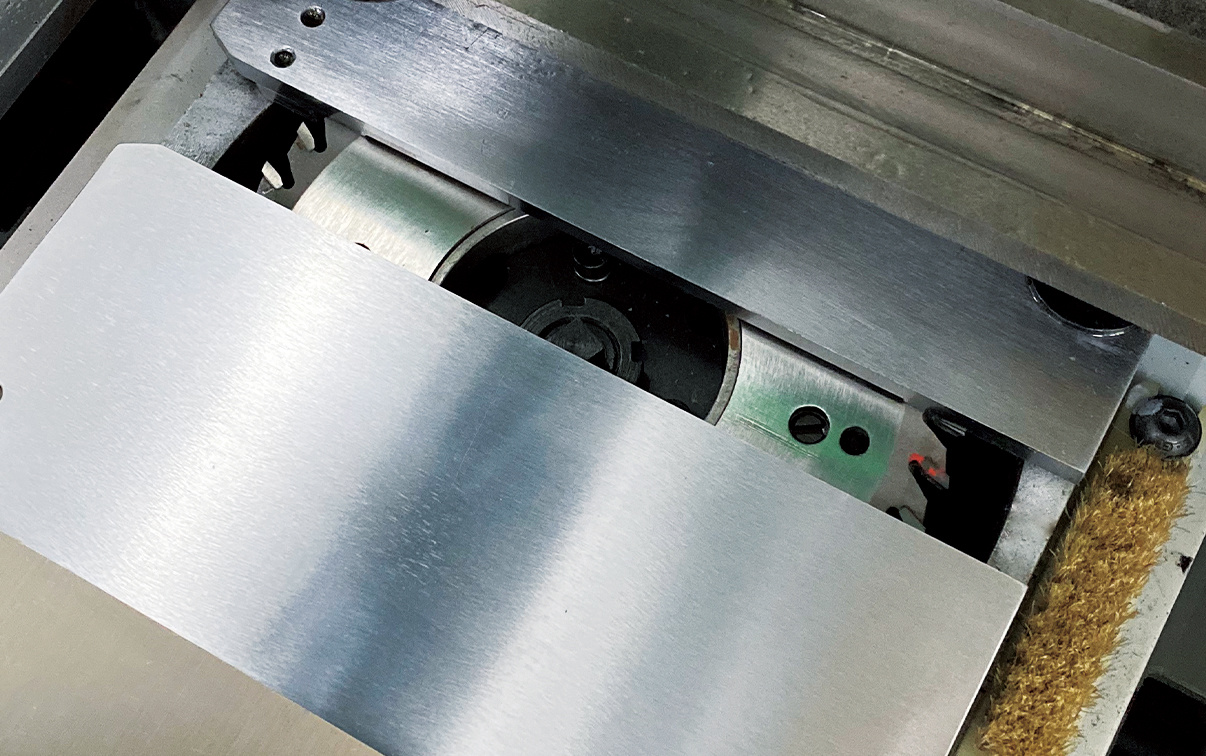

Spine Preparation System

Spine milling, notching, and brushing. Milling plate opening width is easier for adjustment thanks to the position indicators, with milling depth adjustable from 0~3mm. Operator can easily enable and disable milling as needed. |

|

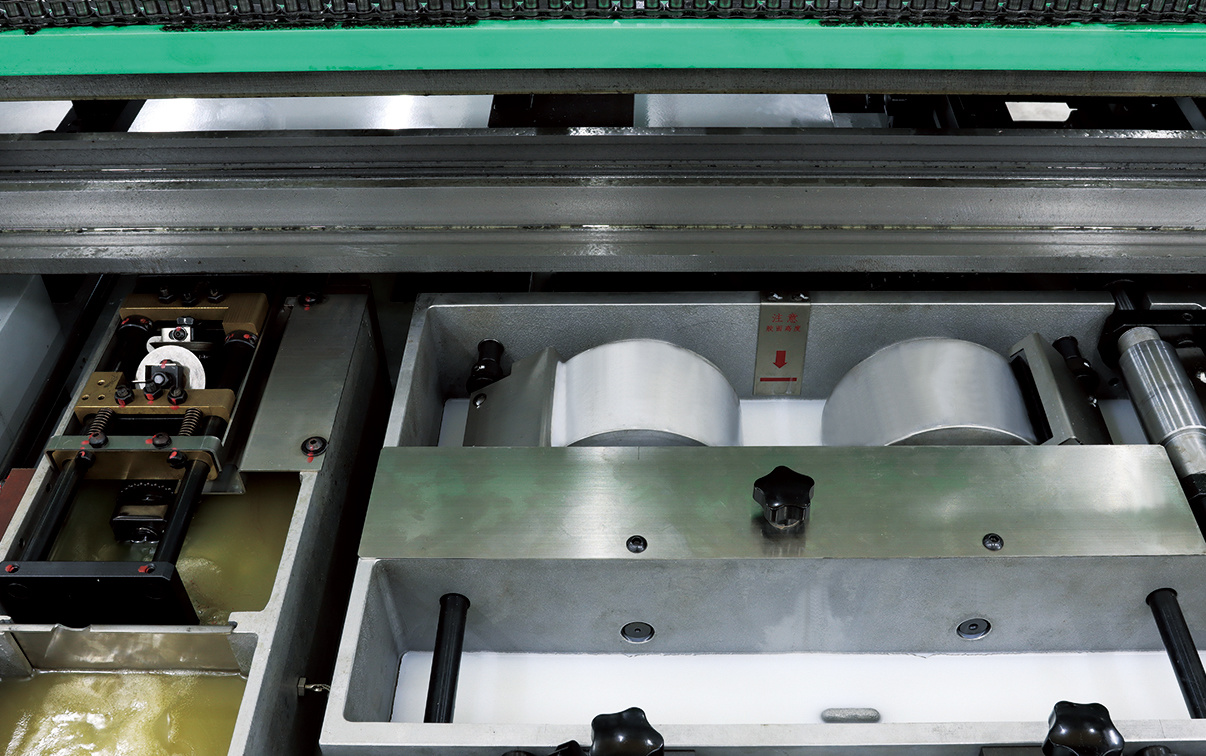

Side Gluing Station

Two application discs ensure even side glue application to the two sides of book spine. Opening width of side gluing disc is adjusted by position indicator. Spine Gluing Station Dual spine gluing application rollers and a glue evening roller ensure superior glue application to the book spine for optimal binding quality. Glue length cut-off is regulated by cam structure. |

|

Nipping Station

Thanks to the strong and rigid nipping mechanism, covers can be precisely and firmly nipped with the book blocks to obtain perfectly-shaped book spines. The opening width of nipping plates and side gauges are easier for adjustment thanks to position indicators. |

|

Machine Model |

Superbinder-200E |

|

No. of Clamps |

4 |

|

Max. Mechanical Speed |

2000 c/h |

|

Book Block Length (a) |

140-450mm |

|

Book Block Width (b) |

120-270mm |

|

Book Block Thickness (c) |

3-50mm |

|

Cover Length (d) |

140-450mm |

|

Cover Width (e) |

240-620mm |

|

Machine Weight |

1900kg |