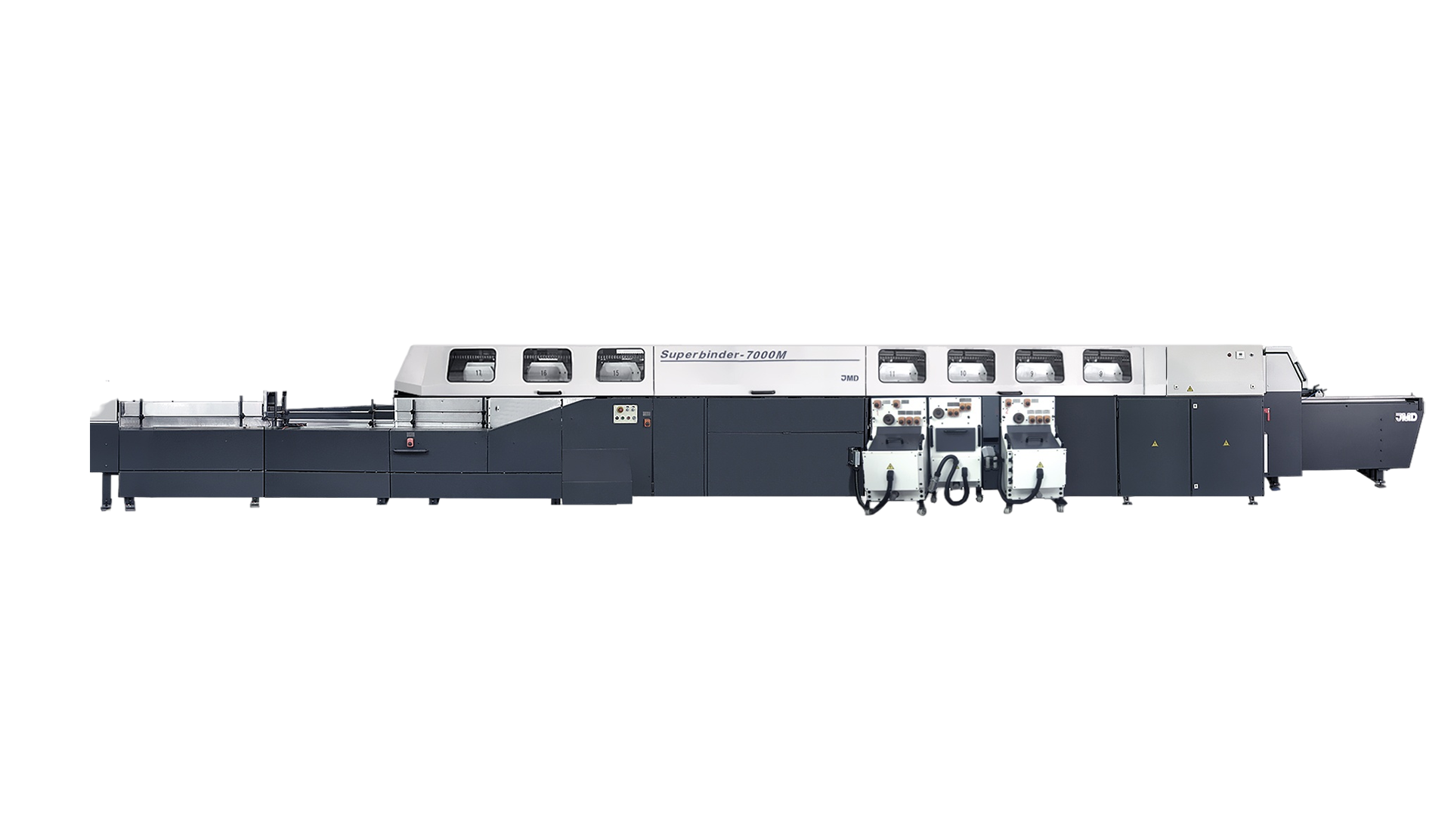

Superbinder-7000M Perfect Binder

Superbinder-7000M is an ideal binding solution to fulfill your every demand for high production efficiency and quick return of investment. It features easy operation and setup, double spine gluing stations and double nipping stations for perfect spine forming.

Outstanding Features:

♦ High net output at 7000 cycles/hour with thickness up to 50mm.

♦ Four spine preparation stations for spine roughening, milling, notching and brushing.

♦ Position indicators provide user-friendly operation and precise adjustments.

♦ Durable construction with using of high quality European imported spare parts as key parts.

♦ Optional Gauzing Station and PUR glue application system to meet different demands.

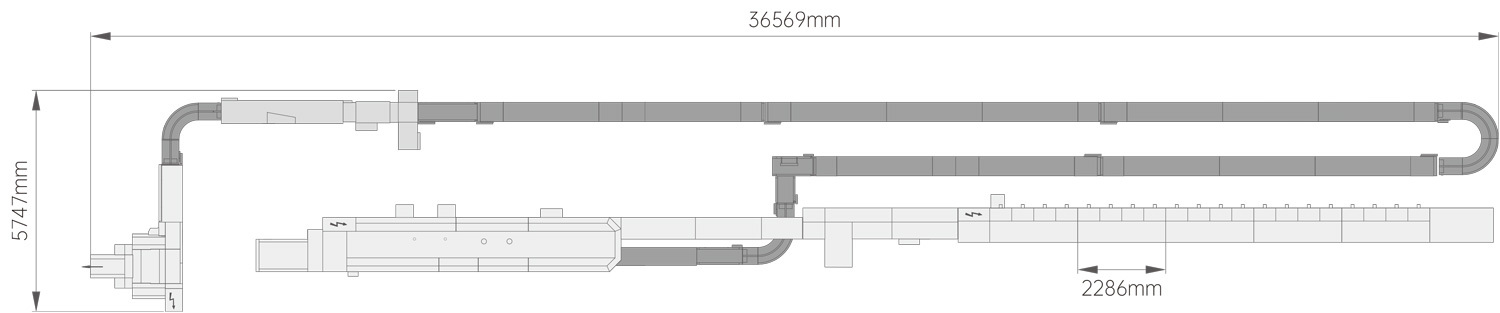

Machine Layout:

|

Spine Preparation Stations

Four separate spine preparation stations provide for spine roughening, milling, notching and brushing, which ensure the book spine is well prepared before glue application. |

|

Gluing Application System

Double spine gluing station with one side gluing station guarantee optimal gluing effect. Movable gluing stations allow easy changeover between PUR and EVA binding methods. |

|

Stream Cover Feeder and Scoring Station

Large capacity stream cover feeder allows stable feeding of large quantity covers for medium and long print runs. The specially designed dual axis scoring rollers with large diameter enable straight and nice-looking scoring lines. |

|

Two Nipping Stations

Two superior nipping stations exert powerful nipping pressure to create strong, durable binds with perfectly-shaped book spines. |

|

机Machine Model |

Superbinder-7000M |

|

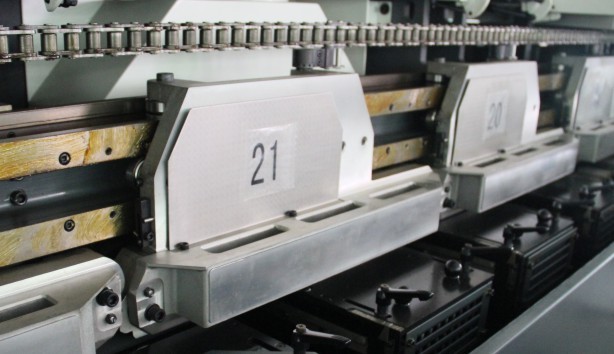

No. of Clamps |

21 |

|

Max. Mechanical Speed |

7000 c/h |

|

Book Block Length (a) |

140-460mm |

|

Book Block Width (b) |

120-300mm |

|

Book Block Thickness (c) |

3-50mm |

|

Cover Length (d) |

140-470mm |

|

Cover Width (e) |

250-640mm |